- PVA Industrial Vacuum Systems GmbH

- Company

- News, Dates and Exhibitions

- Archive

- Sintering of hardmetal for high-end applications

Hardmetal - the perfect choice for many applications

26.05.2021

Hardmetal, a sintered composite material made of cobalt and a ceramic (usually tungsten carbide), has become indispensable in the machining and non-cutting processing of a wide variety of materials. The combination of particularly high hardness coupled with very good toughness, high operating temperatures and a good ability for coating makes hardmetal the first and most economical choice for many applications. From a manageable number of grades, properties and shapes years ago, a very wide range of special solutions has developed over the years and the demands on the know-how of the manufacturers and on their production facilities are high.

Carbide specialists and technology leaders: Boehlerit

Boehlerit, which is headquartered in Kapfenberg, Austria, has many years of expertise in metallurgy and state-of-the-art coating and pressing technology - the company's core competencies. Expenditure on research and development amounting to 5% of sales also supports the permanent further development of processes and products at a high level.

Boehlerit places great emphasis on the development and design of quality products that are as durable and recyclable as possible, environmentally friendly measures in their manufacture and minimal environmental impact in the operation of the products.

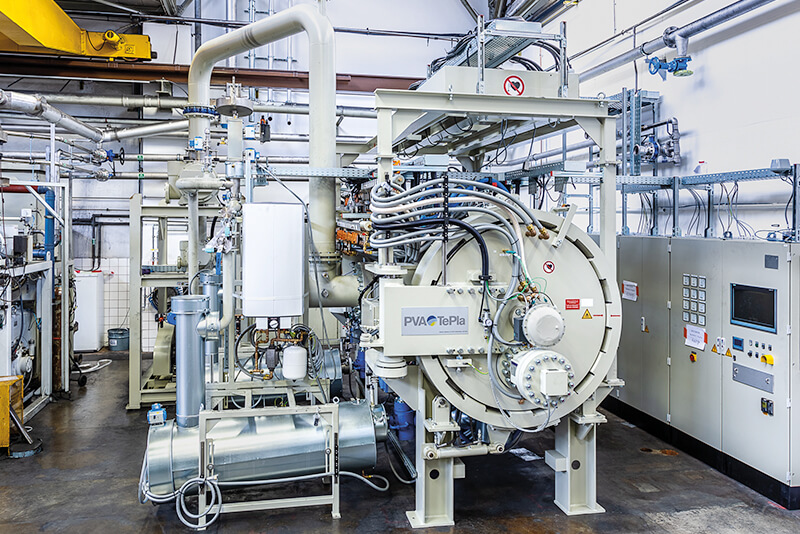

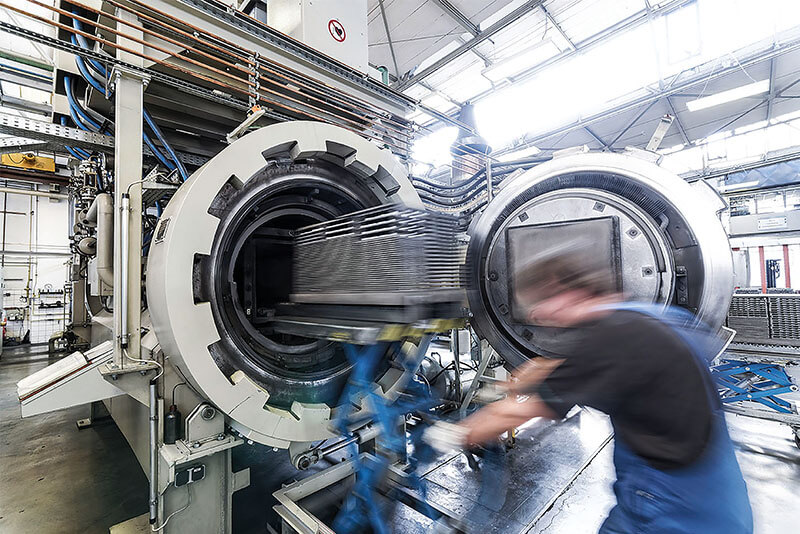

Martin Willinger, the company's production manager, has been with Boehlerit for over 30 years. "Process-optimized sintering sequences are particularly important to us. For quality reasons, Boehlerit sinters exclusively in HIP sintering furnaces (HIP: Hot Isostatic Pressing), which are designed for pressures of up to 100 bar. We place the highest value on uniformity, high cooling rates and safe operation."

Advantages of using a PVA Sinter-HIP furnace

- Wide product portfolio: volume production or fast & flexible response to customer requirements with the same high quality.

- Reduction of cooling time by approx. 15 - 20%.

- Significant reduction of dewaxing time due to double dewaxing equipment

- Uniformity of metallurgical results

- Innovative control concept allows a big step towards Industry 4.0 with data exchange, remote maintenance and process documentation

The systems are used at all production locations, which enables redundant production and consistent quality standards.

Boehlerit wants to remain a technology leader in the future and is investing more in markets and products that are not dependent on economic crises. Martin Willinger: "In this regard, we like the proactive approach of PVA TePla, which supports us with innovative ideas and drives joint developments."