PVA Industrial Vacuum Systems GmbH offers vacuum brazing systems servicing a wide range of industries. Our team of experts can advise you in detail. PVA also has an in-house full service R&D team, and facilities, that can help you get started. Go to PVA TePla LWT

The plant types

PVA TePla's vacuum brazing systems, electrically heated batch systems for brazing and high-temperature brazing processes, are designed for temperatures of 800 °C to 1.300 °C, in individual cases also up to 1.700 °C. All plants of this type have active gas cooling units in order to be able to cool the brazing batches to room temperature as fast as possible.

Plants for large series with steel or copper materials

The COV system type is generally used for robust high-volume brazing applications in which steel or copper materials are joined. Characteristic of this product line is a robust heating element with heating conductors made of graphite, a graphite soft felt insulation, as well as an oil diffusion pumping station. COV brazing systems can also be used for brazing superalloys or other materials that require increased purity of the furnace atmosphere.

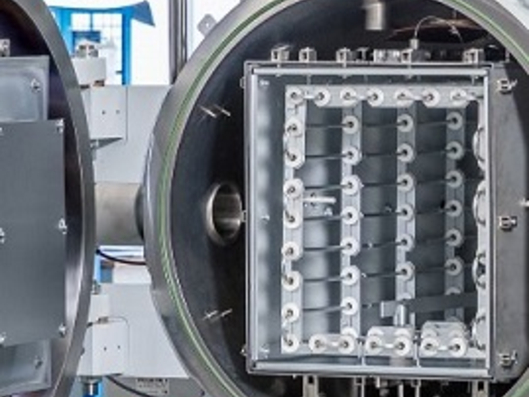

Equipment for extremely reaction-sensitive materials

The MOV type vacuum brazing systems, mostly high vacuum systems, are fully metal lined and have heating inserts constructed of molybdenum or tungsten. The atmosphere is low, to zero hydrocarbon, and therefore ideal for use with reaction-sensitive materials such as titanium, niobium, zirconium or tantalum. Work is carried out in high or ultra-high vacuum, thus meeting the most stringent requirements for brazing atmosphere quality, e.g. in the manufacture of vacuum interrupters. Typically, the MOV systems have turbomolecular or cryogenic vacuum pumping units integrated into the plant.

Application areas and markets

Vacuum brazing processes have a wide range of applications in a wide variety of industries such as aerospace, energy technology, electromobility and others. Thermal applications in these industries often require high-purity process atmospheres.

Typical workpieces created in this way include:

- Heat exchangers and cold plates (heating, cooling)

- EGR cooler

- Diamond and carbide tools

- Turbine parts (gas turbines, aircraft turbines)

- Vacuum interrupters

- Electron tubes

- Feedthroughs (power feeds, etc.)

- Rotary anodes for X-ray apparatus

- Instruments (pressure probes, thermocouples, sensors)

- Machine parts (pistons, housings, burner parts)

- Components in mold making (near-contour cooled molds)