- PVA Industrial Vacuum Systems GmbH

- Markets

- Aerospace

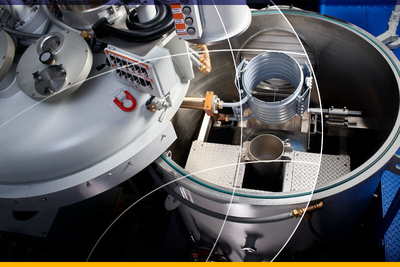

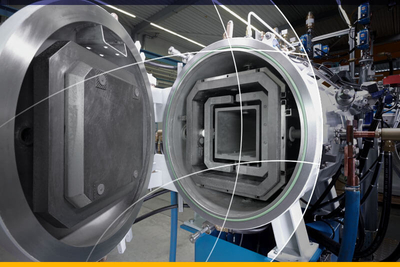

Aerospace is one industry in which maximum reliability and durability are very much in demand. New materials and production processes present major technological challenges to manufacturers. We deploy our comprehensive process expertise and our Innovation Lab to help our customers to deal with new technologies and enable the production of high-alloy materials and components for applications such as turbine manufacture. With AMS-compliant systems technology and energy-efficient systems of various sizes—from laboratory scale to production standard—we offer our customers dependable process stability. Our systems enable even the sintering of large SiC space telescopes as well as partial plasma nitriding.

- Heat treatment of metal materials

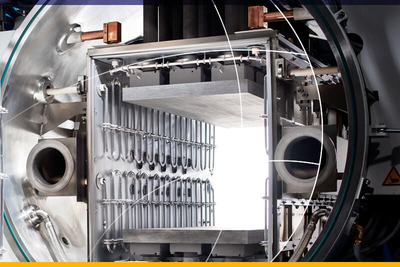

- Cleaning and CVD coating of graphites

- Brazing and diffusion bonding of turbine parts (gas and aircraft turbines)

- PulsPlasma® nitriding/nitrocarburizing (430 °C–600 °C) of components made of steel, cast iron, and sintered iron to increase resistance to wear and corrosion

- Low-temperature PulsPlasma® nitriding and nitrocarburizing (350 °C–430 °C) of tools and components made of rust- and acid-resistant stainless steel to increase wear resistance without sacrificing corrosion resistance

- High-temperature PulsPlasma® nitriding (600 °C–900 °C) of components made of titanium or titanium alloys

- Oxidation/post-oxidation of steel components for increased corrosion resistance and/or reduced friction of surfaces

- Sintering of cemented carbide cutting and wearing tools

- Plasma cleaning and surface activation of components to optimize preparation for subsequent diffusion processes

- Monocrystalline vertical-gradient freeze processes, such as for turbine blades, using vacuum casting

- Infiltration Technology

- Brazing of turbine parts, repair brazing of turbine blades

- Diffusion bonding of turbine blades and other power plant parts

- Alloy production (high-alloy metals)

- PulsPlasma® nitriding, low-temperature PulsPlasma® nitriding and plasma nitrocarburizing of turbine parts made of high-alloy special steels

- PulsPlasma® nitriding of aircraft undercarriage components

- PulsPlasma® nitriding of satellite components made of high-alloy steels