- PVA Industrial Vacuum Systems GmbH

- Technologies

- Infiltration Technology

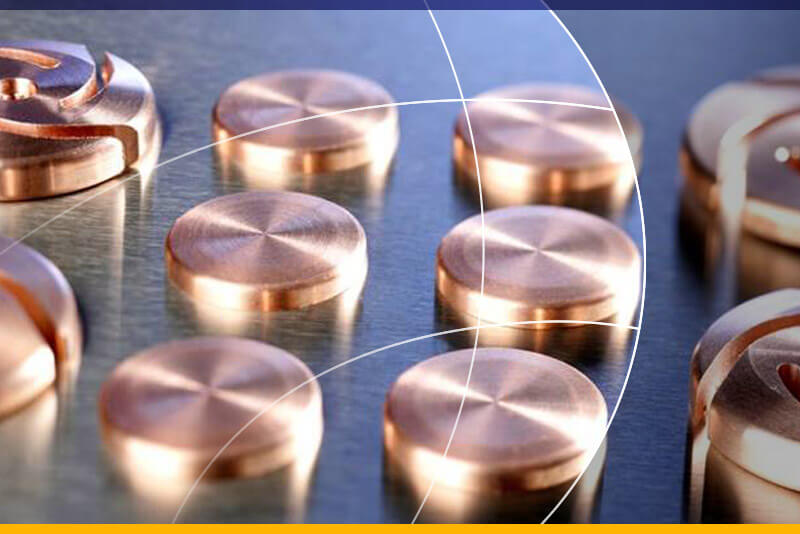

Composites with special characteristic profiles can be manufactured with the aid of infiltration processes. The principle involves taking a porous body with a high melting point and filling it with a (usually ductile) metal with a low melting point in liquid form. For example, infiltrating copper into a body made of porous carbide produces a contact material with good conductivity and high abrasion resistance. To achieve this, filler material is first melted and then introduced to the porous body. This can be carried out at atmospheric pressure or via capillary action, or with the aid of gas pressure. Factors such as infiltration speed and the specified direction of solidification play a major role in this.

The decades of experience and impressive qualifications of our staff coupled with close cooperation with leading composite manufacturers are the essential elements that enable us to offer infiltration systems to suit any customer.

About our

infiltration systems