-

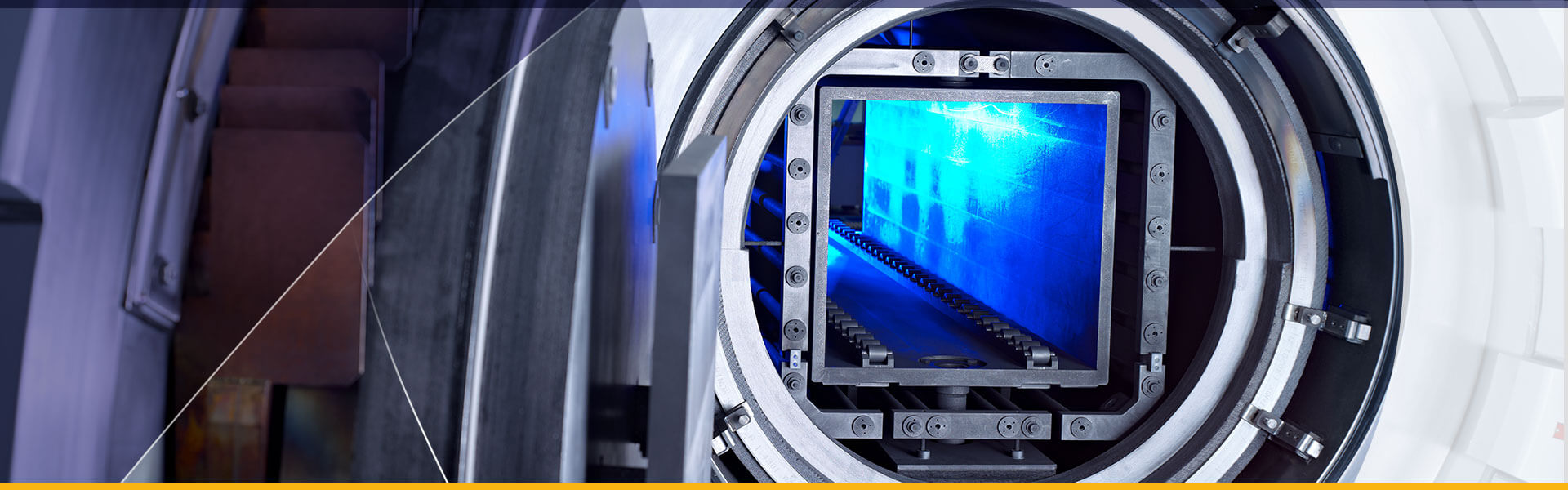

COD Furnaces for Cemented Carbide

PVA Sinter-HIP systems of the "COD" series are designed for vacuum sintering and overpressure sintering of hard metals at application temperature up to 1600°C. The systems are available in pressure levels of 60, 100 and 200 bar overpressure. PVA offers many different sizes of these systems, from laboratory scale (approx. 50 l useful volume) to large production systems with approx. 900 l useful volume.

Furnace COD 733 RL

Effective length: 1,800 to 3,000 mm

Designed for mass production of cemented carbide parts.

Furnaces with an effective length of 1,800, 2,000, 2,200, or 2,400 mm have four temperature control zones, while those with an effective length of 2,500, 2,700, or 3,000 mm have six. For all long furnaces with six control zones, there is an option to fit a second condenser channel.

-

PVA TePla Sinter-HIP systems for sintering of non-oxide ceramics are designed for application temperatures of 1900°C or 2200°C and 60 bar overpressure. The furnaces can be supplied in vertical design according to the industrial standard, or as a maintenance-friendly and easy-to-handle horizontal system.

-

Unlike the COD Sinter HIP Furnaces are sold as part of project business, the SSH (Smart Sintering HIP) is a standard pressure sintering furnace from PVA. Its size and functions are pre-defined by PVA, and there are restrictions on how much it can be customized. Using the same components, materials, suppliers and assembly team means that there are no compromises in terms of the quality of the SSH furnace relative to the COD series. The product character of the SSH furnace dispenses with the customized design and the scope of testing, which is reflected in its affordable price. The SSH furnace is currently available with an effective length of 1,500 mm and operating pressure of 60 bar. It also features vacuum dewaxing, with H2 dewaxing available as an optional extra.

PVA vacuum- and Sinter HIP (Hot Isostatic Pressing) Furnaces are generally equipped with debinding apparatus that can be used to remove pressing additives cleanly and uniformly from the carbide parts before the parts are exposed to the high temperatures involved in sintering. The debinding technology is adapted to the pressing additives used, while the processes are conducted at positive or negative pressure, with inert gases, or in hydrogen atmospheres. In some cases, the parts are treated with reactive gases in the pre-sintering phase to increase the proportion of carbon in the parts or their barrier layers, for example.

Our furnaces require only very short process times thanks to their highly effective cooling systems. This is very much appreciated by our customers since it means that they can adapt their furnace processes precisely to fit production shifts.