PVA Industrial Vacuum Systems GmbH offers the heat treat industries highest quality vacuum sintering systems, manufactured today, for various industries. Furnace design and construction are tailored to meet your specific material requirements and product volume through-put. Share with us your engineering requirements. Our experts will return to you a detailed analysis and guidance on the best system options to meet your needs.

The plant types

Our vacuum sintering systems are modular in design and can be customized to the respective sintering task up to a working temperature of 2.200 or 2.400° C. For carbon-sensitive applications, vacuum sintering systems with a metallic heating insert are a possibility.

Vacuum sintering plant for materials without increased carbon sensitivity

The COV vacuum sintering systems, using graphite heaters, enable cost-optimized production of steels, hard metal materials, non-oxide ceramics and other composite materials. PVA’s leading edge application-adapted design, uses an optimized number and arrangement of the control heating zones, yielding a temperature uniformity across the entire vessel of a maximum of ±°3 C.

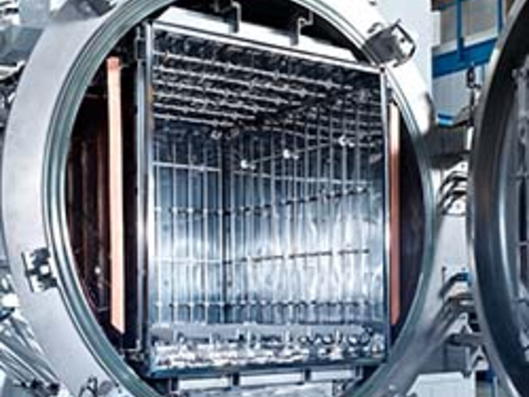

Vacuum sintering plant for carbon-sensitive materials

MOV type vacuum sintering systems with metallic heating elements are used for carbon-sensitive applications and demanding materials. These plants are equipped with power-controlled resistance heating elements made of refractory metals. Applications include both manufacturing and laboratory environments. MOV plants are cold-wall furnaces with a double-walled shell made of stainless steel. Beyond standard applications e.g. with 1600°C, sintering temperatures up to 2,400° C can be realized for special materials.