20/12/2021

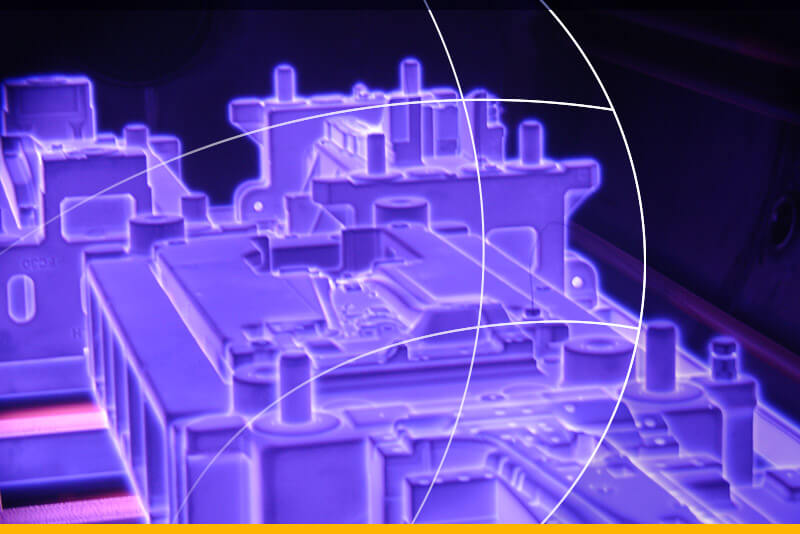

How does Plasma Nitriding work?

Plasma Nitriding is a surface hardening process that is gentle on materials and produces hard and wear-resistant surface layers on filigree to solid components. In Plasma Nitriding, nitrogen is selectively diffused into the surface of steels, stainless steels and Nitride forming materials (e.g. Titanium, Aluminium) in an electrically charged gas atmosphere (= Plasma).

The Plasma Nitriding process is used to increase the surface hardness of the functional surfaces of components, giving them greater resistance to wear.

When treating unalloyed and low-alloy steels, Plasma Nitriding can additionally increase the corrosion resistance of the treated parts.

HÄRTHA - WEISSENBURG stands for perfect metal finishing through heat treatment processes and hardening techniques. The use of state-of-the-art process and control technology optimises Plasma Nitriding in the HÄRTHA hardening shops. The high degree of automation combined with the experience of the experts ensures the required quality and the properties of components desired by the plasma nitriding process.

The company is a valued heat treatment partner for over 1000 customers throughout Bavaria. The company's own logistics department guarantees the timely and flexible collection and delivery of the heat treatment goods.

In 2005, HÄRTHA decided to purchase its first Plasma Nitriding system. PlaTeG was among the suppliers.

"With the PlaTeG system from PVA Tepla AG, the package simply fitted," says Thomas Bückert, managing director of the company.

There are now 6 PlateG-PulsPlasma®Nitriding systems in the production hall at the Cadolzburg plant, and the seventh will be delivered shortly. All 7 systems will then be fully utilised. This makes HÄRTHA - WEISSENBURG one of the largest companies in Germany to have such a large number of Plasma Nitriding systems in one production hall.

According to Mr Bückert, the advantages of Plasma Nitriding are obvious:

In addition, in the case of partial nitriding of component surfaces, the areas that are not to be nitrided can simply be protected by metallic covers. In the simplest case, these can be steel screws that are screwed into the threads to be protected before plasma nitriding.

In contrast, gas nitriding requires the time-consuming application of special stop-off paints and their subsequent removal, e.g. by sandblasting. This eliminates two work steps at the same time.

HÄRTHA Weissenburg GmbH supplies customers in many industrial sectors. One focus is the treatment of parts for the automotive industry - especially for Hybrid technology and increasingly for e-mobility. However, companies in the aviation industry, medical technology and tool and mould manufacturers are also frequent and welcome customers.

After the second PlaTeG system was installed and the high system availability and process reliability were confirmed, the decision was clear: HÄRTHA will stay with this manufacturer - also in the future.

"The same processes can be run in every plant, we receive very good service and can always rely on PVA TePla," says Mario Neuwerth, the company's authorised signatory.

E-mail: ivsinfo(at)pvatepla.com

Web: www.pvatepla-ivs.com